light gauge steel roll forming machine Introduce:

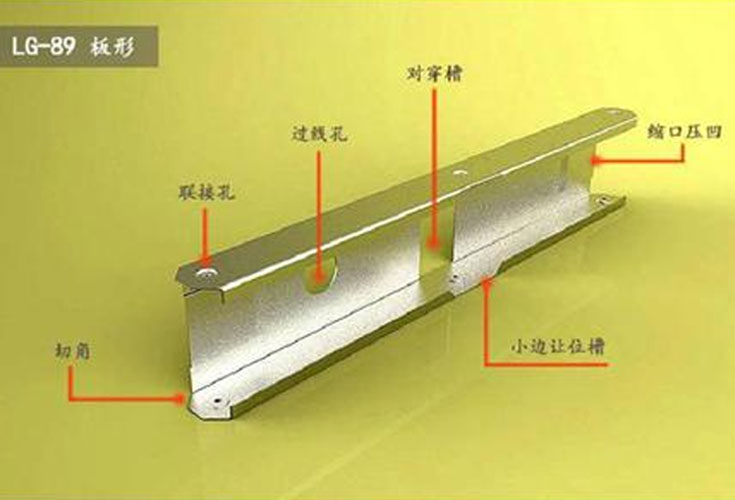

Light steel forming unit consists of material automatic unwinding and discharging machine, material leveling device, forming machine, automatic punching, cutting, receiving table and control cabinet. According to the specific requirements of light steel villa construction, it is equipped with: dimple screw hole, chamfer, web through hole, small side shear, pipeline hole, web shrinkage, shearing and other stamping die and coding device. It adopts professional-grade industrial computer CNC automatic control, which has the characteristics of wide application range, high product precision, high degree of automation, material saving and high degree of automation. It is aimed at the continuous innovation of assembly buildings and diversified structural forms on the market. Special equipment can be designed and manufactured according to customer requirements, and supporting equipment such as floor decking/adjustable C steel can be provided.

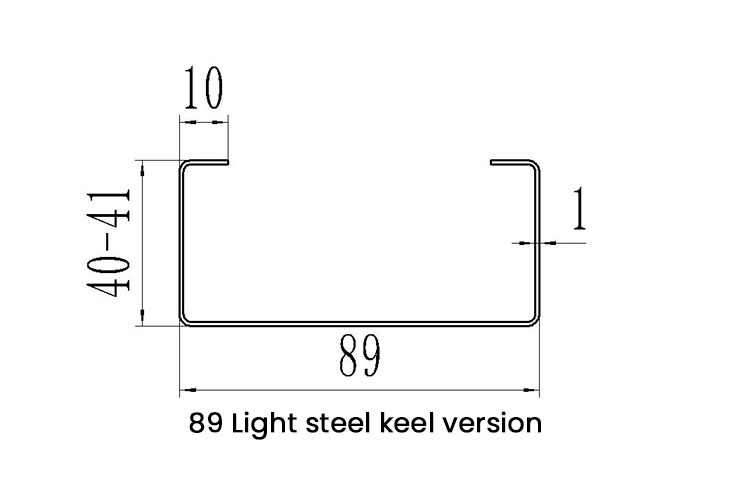

89 light gauge steel machine Technical Plan

light gauge steel roll forming machine Equipment Exhibition

| Basic Parameters Of light steel frame machine | |

| Section size | 140*41mm |

| Material thickness | 0.75-1.2mm (G300-G550 galvanized, galvanized plate) |

| Material width | 233mm |

| Standard production speed | 30m/min |

| maximum production speed | 50m/min |

| monitor rate | 7.5kw |

| Power requirements | 3-phase 380V 50Hz can be configured as required |

| Hydraulic power | 5.5kw |

| Hydraulic tank capacity | 100L |

| Hydraulic cooling | air cooling |

| Hydraulic pressure adjustment | computer settings |

| Host cordless remote control | Standard configuration |

| Frame and Truss Stamping Dies | Dimple screw holes, chamfers, web through holes, small edge shears, pipelines Holes, web shrinkage, shear, web foundation holes, grouting holes |

| Product accuracy | +- 0.5mm |

| Inkjet printer | Dual nozzles, waist-high spraying on both sides, can be set when printing |

| Machine size | 5000*1000*1600mm |

| Machine weight | 3000kg |

| Machine color | According to our company's standards |

| Uncoiler | Load 4000kg, automatic unwinding |

HENER MACHINERY: Setting the Standard with Our Light Steel Frame Machines and Cold Roll Forming Equipment

At Hener Machinery, we are committed to delivering excellence in the manufacturing and supply of light steel frame machines for sale and cold roll forming machines. Our 140 light gauge steel roll forming machines are designed to meet the evolving demands of the construction industry, offering a blend of efficiency, quality, cost-effectiveness, design flexibility, and competitive pricing. Here's an in-depth look at the features that make our equipment stand out.

1. Efficiency and Automation

Our light steel frame machines and cold roll forming machines are engineered for efficiency and high-speed production. The machines are equipped with an automatic material unloading and discharging system, ensuring a smooth and uninterrupted workflow. The integration of a professional-grade industrial computer with CNC automatic control allows for a high degree of automation, which translates to a standard production speed of 30m/min and a maximum speed of 50m/min. This automation not only increases the speed of production but also enhances the overall efficiency of the operation, making our light steel frame machines and cold roll forming machines a top choice for construction projects.

2. Quality and Precision

Quality is at the heart of everything we do at Hener Machinery. Our light steel frame machines for sale are built to last, utilizing high-strength materials such as G300-G550 galvanized or galvanized plate, with thicknesses ranging from 0.75-1.2mm and a material width of 233mm. The precision engineering of our machines is evident in the product accuracy, which is maintained within +- 0.5mm. This level of precision ensures that every component produced by our cold roll forming machines is reliable, durable, and meets the highest quality standards required for light steel villa construction.

3. Cost-Effective Solution

Our light steel frame machines and cold roll forming machines provide a cost-effective solution for construction needs. The energy-efficient design, with a monitor rate of 7.5kw and power requirements that can be configured as required, helps to reduce operational costs. Additionally, the hydraulic power system, with 5.5kw and a 100L hydraulic tank, contributes to material savings and increased productivity. By choosing our light steel frame machines for sale, you are investing in equipment that offers a high return on investment, with lower long-term costs and increased efficiency.

4. Design Flexibility

Hener Machinery's light steel frame machines for sale are designed with flexibility in mind. They come with a variety of stamping dies and coding devices, such as dimple screw holes, chamfers, web through holes, small edge shears, pipeline holes, and web shrinkage options. This range of features allows our machines to cater to the specific requirements of light steel villa construction and the diverse structural forms demanded by the market. We also offer the customization of special equipment according to customer requirements, ensuring that our light steel frame machines and cold roll forming machines can meet any project's unique needs.

5. Competitive Pricing

At Hener Machinery, we understand the importance of offering competitive pricing for our light steel frame machines for sale and cold roll forming machines. Our strategic manufacturing location and efficient production processes allow us to keep costs down without compromising on quality. This enables us to provide our customers with high-quality machines at prices that offer excellent value for money. When you invest in a light steel frame machine from Hener Machinery, you can be confident that you are receiving a product that is both economically priced and built to last.

In conclusion, Hener Machinery's 140 light gauge steel roll forming machines represent the pinnacle of efficiency, quality, cost-effectiveness, design flexibility, and competitive pricing in the industry. Our commitment to innovation and customer satisfaction ensures that our light steel frame machines and cold roll forming machines are the ideal choice for businesses looking to enhance their production capabilities and deliver top-quality construction components. Choose Hener Machinery for your light steel frame machine needs and experience the difference for yourself.