Cable Tray Making Machine Quotation list

Part 1 5Tons Hydraulic Decoiler and loading car

| 1 | Decoiler size | Length 2.5 Mtr x Width 1.6 Mtr x Height x 1.75 Mtr |

| 2 | Weight | About 2600kgs |

| 3 | Hydraulic station | 5 Solenoid valve pump station, 3kw, 380v |

| 4 | Main power | 4kw |

| 5 | Frame | Bottom 300H steel, fame 16mm thickness steel plate |

| 6 | Supporting Spindel | Made of thick-walled seamless steel pipes, shaft diameter 194x45mm |

| 7 | Coil width | 0-1500mm |

| 5 Ton Loading Car | ||

| 1 | Car Lifting | Double oil cylinder, cylinder diameter 90mm, stroke 240mm |

| 2 | Car move forward | Model 450, hydraulic motor |

| 3 | Loading face | Length 1.25 Mtr, width 1.1 Mtr |

| 4 | Car Track | Width 1.05Mtr, length 2.5 Mtr |

| 5 | Car Travel | Height travel: 400mm, Length travel: 2.5Mtr |

| 6 | Car weight | About 900kgs |

Part 2 Material Feeding Guider

1. Positioning plate: Adjust the position of both ends to make it fit the width of the feeding.

Part 3 Leveling Device

1. Leveling roller upper 5 roller, down 4 rollers

2. Leveling roller diameter: 100mm

Part 4 Punching Device

1. Hydraulic punching, all holes required for punching profiles at one time, adjustable punching row spacing

2. Cylinder: 25ton x 2

3. Hydraulic power: 11kw

Part 5 Hydraulic pre-cutting Device

1. Hydraulic front shearing, stop cutting, no waste

2. Cylinder: 15 tons

3. Blade material; Cr12 Heat treatment HRC58-62

Part 6 powered transmission table

1. Power flat roll, motor drive, screw width adjustment

2. Length 6 mtrs

Part 7 Main Roll Forming Mill

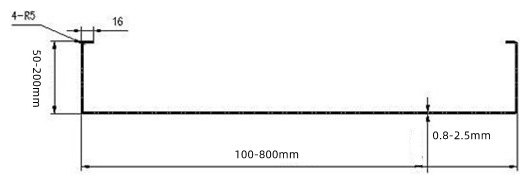

1. Automatic continuous roll forming, manual + automatic control, motor drive, stepless adjustment in the range of width 100-800, height 50-200, electric control to adjust the above parameters

2. Forming frame: H400 section steel welded with 25mm table top, the whole is shot blasted and sanded to remove rust. Multi-hole gantry milling machine table and connection port.

Cable Tray Manufacturing Machine inspection

1. The seller will inform the buyer come to check the machine 7 days in advance.

2. The seller will prepare the material to test the machine.

Remark: we will provide the full machine running video and photos to the buyer , Or at the factory with the customer video, If the buyer not come to check.

Service & Warranty

1. Payment Term: 30% of machine value as deposit is paid by T/T, 70% of machine value is paid by T/T before loading machine into the container after the customer's inspection.

2. Delivery Time: Within 50-60 days after receiving deposit

3. Service & Warranty:

1). Our machine warranty is 12 months (non-man-made damage, accessories, technical support)

2). Technical guide is provided during whole life of the machine.

3). Oversea services will be provided but any cost thus incurred will be paid by the buyers.

4). We support customers inspect our factory or machines by video call.

5). Voltage can customize according to customers' requirement.

6). If need more machine pictures or videos, please contact me soon.

4. Packing Method: Main machine is nude; the computer control box is packed by carton box or with PE film, then steel wire fixed.

5. Transportation: the machine need two 40 feet container to hold

6. Something prepared before production: Our machine is ready to product when you get it. Customers only need to prepare the hydraulic oil and electrical wires.

7. How to unload from the Container: Need Cranes and forklifts.

8. Maintenance: Instructions are attached to the shipment

9. Assembly (Optional):

1) if you need our engineer to install,The installation charge is $150 per day.

2) The buyer has to pay the seller's technician: Travel cost outside China (Including round flight charges), accommodation and foods (At least three-star hotel with air condition), solve the language problem, provide transportation from living place to the work place, and insurance out of China, etc.

Our company is a factory with 17 years of production experience specializing in the production of outdoor cable tray roll forming machine, and currently ranks high in China's production of cable ladder machine. Our products have good materials, and our customers are mainly distributors and downstream manufacturers. We can provide customized services according to customer needs. Our company has a high annual production capacity, complete specifications, large inventory, and fast delivery, which can reduce customer stocking pressure.

1.Cable Tray Machinery: A cable tray manufacturing machine is a specialized equipment used for manufacturing cable trays and cable ladders. Cable tray manufacturing machine efficiently forms metal coils into cable tray profiles of various shapes and sizes, including outdoor cable tray roll forming machines. As a reputable cable tray making machine manufacturer, our company offers custom-designed machines that meet specific production requirements. Our factory incorporates advanced technology and precise manufacturing processes to ensure high-quality and durable machines.

2.Advantages of Cable Tray Making Machine: Cable tray roll forming machines offer several advantages. They provide high production efficiency, precise forming of profiles, and consistent product quality. The machines are customizable to produce cable trays and ladders with different specifications. Our outdoor cable tray roll forming machines are designed to withstand harsh environmental conditions. As a leading manufacturer, we provide reliable machines that enhance productivity and reduce production costs.

3.Generation Process of Cable Tray Making Machine: Our cable tray roll forming machines are manufactured through a rigorous process. It includes design and engineering, selection of high-quality materials, precise machining, assembly, and testing. Our experienced engineers and technicians ensure that each machine meets the required specifications and quality standards. The production process is carried out in our state-of-the-art factory using advanced machinery and equipment.

4.Application of Cable Tray Manufacturing Machine: Cable tray roll forming machines have a wide range of applications. They are used in the electrical and construction industries for cable management systems. Cable trays are utilized for organizing and supporting electrical cables in commercial, industrial, and residential buildings. Our machines can produce cable trays and ladders suitable for various installations, including outdoor environments. They are designed to meet the specific needs of cable management systems in different industries.

5.Cable Tray Making Machine Maintenance and Upkeep: Proper maintenance is crucial for the optimal performance and longevity of cable tray roll forming machines. Regular maintenance checks, lubrication of moving parts, and inspection of electrical components are recommended. It is essential to follow the manufacturer's guidelines and conduct routine inspections to identify any potential issues. Our company provides comprehensive support and guidance for machine maintenance, ensuring smooth operation and minimizing downtime. We offer prompt assistance and spare parts whenever required.