cable ladder machine parameters

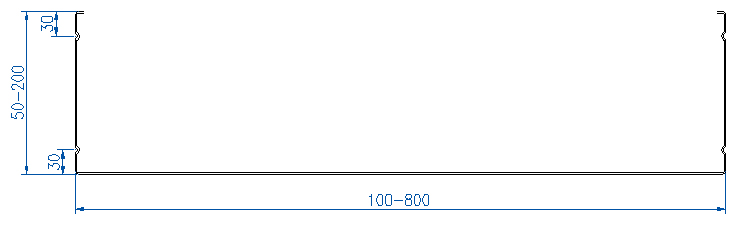

Specifications: 100-800

Rolling thickness: 0.8--2.0mm

Rolling speed: 6-8 meters/minute

Host form: cantilever type

Operation mode: PLC control, manual electronic control, remote control

One set of bridge forming machine: uncoiling - leveling + punching + shearing - six-meter conveying platform - forming machine - discharging

| Uncoiling | Unwinding maximum width 1250mm Inner hole diameter 470-530mm hydraulic tensioning | Hydraulic tensioning | Vertical, load-bearing 5 tons Pumping station power 3.0kw | |

| Leveling machine | Maximum thickness 2.0mm Maximum width 1250mm Plate thickness 35mm | Roller diameter ø90 Three up and four down + two lanes of transportation | Motor power 7.5kw Rolled flat shaft material 40Gr | |

| Seven shaped hole | Seven-shaped hole with mold (2 pieces) | |||

| Cut off | Cutting hydraulic shearing width 1250mm | Pumping station power 11kw | ||

| Conveying | 3 meters × 2 meters (1 piece) | Automatic opening and closing; Speed adjustable | Motor power 0.75kw | |

| Punching | Hydraulic punching | Punching specifications | 50、100.150、200 | Replacement motor power 2.2kw Cylinder diameter Φ160×2 pieces |

| Punching thickness | 0.8-2.0mm | |||

| Punch speed | 8 meters/minute | |||

| Molding | Φ75-26 sorties Base: 400×200, H-shaped Steel welding Cabinet: thickness 25mm Steel plate assembly and welding forming With two rolling bars | Rolling specifications | 100×50—800×200 | Main motor power: 5.5kw*4 units Zhanghe motor power 2.2kw×2 Transmission mode: chain transmission Roller material: 45# |

| Rolling thickness | 0.8-2.0mm | |||

| Rolling speed | 8 meters/minute | |||

| Discharge | Length 3 meters | Without power roller transmission | ||

Electronic control: automatic type change, 4 sets of type change motors, Delta PLC and touch screen, Sanjing inverter, Delixi low-voltage electrical appliances.

Area: 35 meters*3 meters

Total weight: 27 tons

Motor power: 45kw

Construction period: 75 days

cable ladder machine Payment method: 30% down payment, paid in full upon delivery

cable ladder machine Price: 580,000 (excluding tax and shipping)

Cable Tray Machine Manufacturer

A cable tray machine manufacturer is a company that specializes in designing, manufacturing, and supplying cable tray machines, including cable ladder machines and outdoor cable tray roll forming machines. These manufacturers have expertise in producing high-quality and efficient machines for the production of cable management systems.

A reputable cable tray machine manufacturer will offer a range of options to cater to different needs. They understand the requirements of the industry and provide customized solutions to meet specific project demands. Whether it's cable ladder machines or outdoor cable tray roll forming machines, they ensure precision in forming, cutting, and assembling the components.

When choosing a cable tray machine manufacturer, consider their experience, reputation, and track record in the industry. Look for manufacturers with a strong presence and a history of delivering reliable and durable machines. It's important to select a manufacturer that offers excellent after-sales support, including maintenance, training, and technical assistance.

Cost-effectiveness is also a consideration. While seeking affordable options, ensure that the manufacturer doesn't compromise on the quality and performance of the machines. Look for a balance between competitive pricing and the machine's capabilities.

Overall, a cable tray machine manufacturer plays a vital role in providing the necessary equipment for the production of cable management systems. They offer custom solutions, reliable machinery, and expertise to help companies, factories, and businesses efficiently manufacture cable trays, including cable ladders and outdoor cable trays.