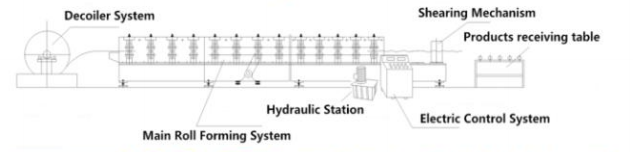

Flow Chart

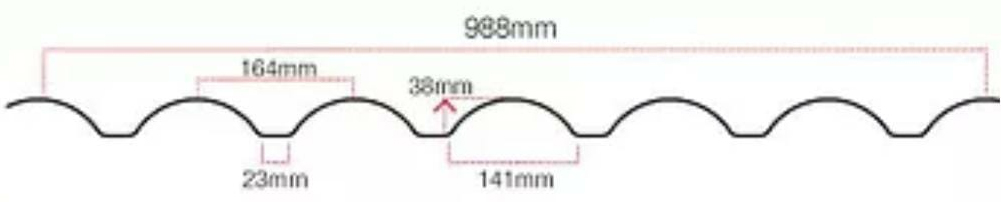

Pattern Diagram

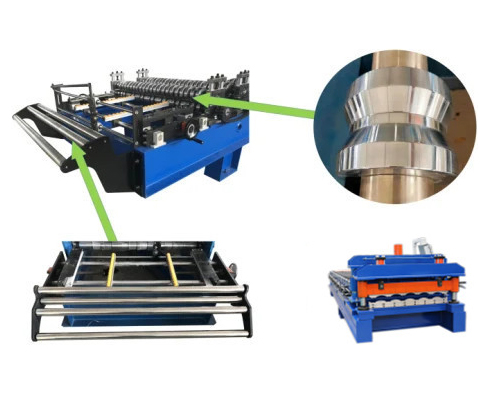

Glazed Roofing Sheet Roll Forming Machine

| NO. | Description | Quantity (set) |

| 1 | 5T manual decoiler | 1 |

| 2 | Guiding device | 1 |

| 3 | Forming system | 1 |

| 4 | Transmission system | 1 |

| 5 | Single pillar hydraulic cut | 1 |

| 6 | Hydraulic pump station | 1 |

| 7 | Electric Control Cabinet | 1 |

| 8 | Run-Out Table | 1 |

| 9 | Spare parts and tools | 1 |

| No | Item | Parameter | Note |

| 1 | Raw material | PPGI / GI / PPGL / GL | Meet your requirement |

| 2 | Thickness | 0.3-0.7 mm | Meet your requirement |

| 3 | Cover Roofing Sheet Size | AS the drawing | Meet your requirement |

| 4 | Feeding width / coil width | As you required | according to your profile drawing |

| 5 | Side wall thickness | 18 mm | Exported standard |

| 6 | Forming Speed | 5-8 m/min | Exported standard |

| 7 | Forming station | 18 stations | Exported standard |

| 8 | Total Power | 7.5kw (main motor power) + 4KW (hydraulic pump station motor power) | More bigger the pump station power, more faster the machine speed |

| 9 | Mill bed material | 350H beams welded, 8mm thick | Exported standard |

| 10 | Voltage | 380 V or as your requirements | special voltage, please let me know |

| 11 | Diameter of shaft | 70mm diameter solid shafts | Exported standard |

| 12 | Chain size | One inch chain | Exported standard |

| 13 | Cutting type | Single Pillar type | Exported high standard |

| 14 | Forming Shaft | 45# steel with grinding process | Exported standard |

| 15 | Forming Roller | 45# steel with hard chrome coating | Exported standard |

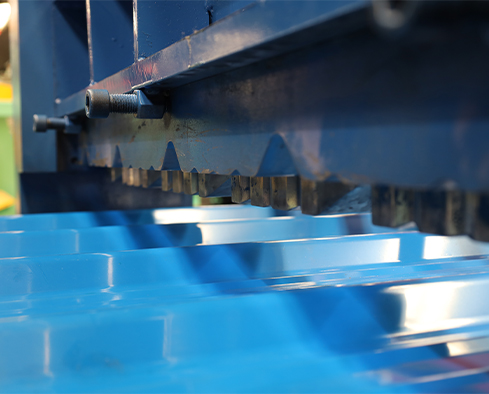

| 16 | Cutting Blade | Cr12 with hard treatment | Exported standard |

| 17 | PLC/Touch Screen | DELTA brands | From Taiwan, China |

| 18 | Electrical motor | SHANGHAI LICHAO brand with outside placed | Top brand, quality tested |

| 19 | Encoder | OMRON Brand with aluminum bracket | From Japan |

| 20 | Machine size | 8.2m * 1.5m * 1.5m | Exported standard |

| 21 | Machine weight | About 7.0 tons | Exported standard |

| Part 1 Manual Decoiler | |

1) Usage: It is used to support the steel coil and uncoil it in a turnable way. 2) Inner diameter: 450-508mm 3) Can bear the max tons is 5 tons |

|

| Part 2 Feeding Part | |

1) Positioning plate: adjust the position of both ends to make it fit the width of the feed. 2) Guide frame: play a role in supporting the transport of the material roll. 3) Guide roller: The upper and lower round rollers are designed to make the feeding process more smooth. |

|

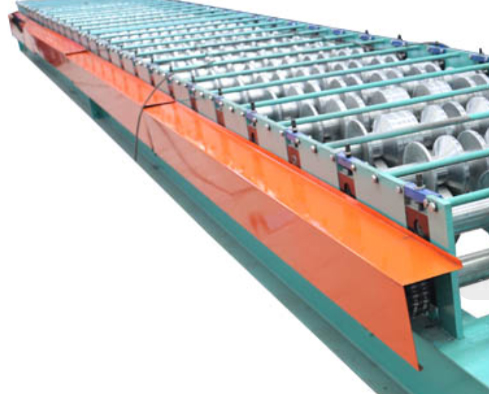

| Part 3 Main roll former | |

1) Roller assembly: 2) Main roller diameter: 70mm 3) Roller material: 45 # steel, Heat treatment, hard chrome plating after finish turning, mirror polishing 4) Frame tie rod: 20 # electroplate round steel to increase rigidity on both sides of wall panel 5) Roll forming: Roll forming process of coil |

|

| Part 4 Hydraulic system | |

1) It is controlled by gear wheel oil pump, After filling the Hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job. 2) Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves. 3) Power: 4KW 4) For let hydraulic station can working long time, we install one wind fan cool system |

|

| Part 5 Automatic shearing system | |

Cutting after forming: 1) Guide mechanism: make the knife holder cut smoothly without deformation of the cut. 2) Cast iron tool holder: obvious shock absorption effect and strong impact resistance. 3) Blade material: Cr12Mov The cutting life exceeds 1 million times. 4) Rear scissor frame: Q235 steel plate, annealing treatment after rough turning, finishing. |

|

| Part 6 PLC Control System | |

1) PLC: Adopt DELTA high-precision PLC electronic device. 2) The whole line is controlled by PLC and touch screen. The PLC system is with high-speed communication module, it is easy for operation. The technical data and system parameter can be set by touch screen, and it is with warning function to control the work of whole line. 3) Control the cutting length automatically 4) Automatic Length measurement and quantity counting 5) Size: 7 inch touch screen and 1020 * 600 * 400mm |

|

| Part 7 High-precision automatic counter | |

One counter gauges length, pulses, and decides length, Omron made in Japan. |

|

| Part 8 out-put table | |

| |

18mm thick side wall panels

70 mm diameter solid shaft

One inch chain

Chain Protection cove

Aluminum bracket, Omron brand encoder

Roll forming machine inspection

1. The seller will inform the buyer come to check the machine 7 days in advance.

2. The seller will prepare the material to test the machine.

Remark: we will provide the full machine running video and photos to the buyer, Or at the factory with the customer video, If the buyer not come to check.

Other items

1. Machine weight: about 7.0T

2. Machine dimension: 8200mm * 1500mm * 1500mm

3. Machine color: blue or According to customer requirements

4. Work voltage: According to customer requirements

Glazed tile roofing sheets making machine Service & Warranty

1. Payment Term: 30% of machine value as deposit is paid by T/T, 70% of machine value is paid by T/T before loading machine into the container after the customer's inspection.

2. Delivery Time: Within 40-50 days after receiving deposit

3. Service & Warranty:

1). Our machine warranty is 12 months (non-man-made damage, accessories, technical support)

2). Technical guide is provided during whole life of the machine.

3). Oversea services will be provided but any cost thus incurred will be paid by the buyers.

4). We support customers inspect our factory or machines by video call.

5). Voltage can customize according to customers' requirement.

6). If need more machine pictures or videos, please contact me soon.

4. Packing Method: Main machine is nude; the computer control box is packed by carton box or with PE film, then steel wire fixed.

5. Transportation: the machine need one 20 feet container to hold

6. Something prepared before production: Our machine is ready to product when you get it. Customers only need to prepare the hydraulic oil and electrical wires.

7. How to unload from the Container: Need Cranes and forklifts.

8. Maintenance: Instructions are attached to the shipment

9. Assembly (Optional):

1) If you need our engineer to install, The installation charge is $150 per day.

2) The buyer has to pay the seller's technician: Travel cost outside China (Including round flight charges), accommodation and foods (At least three-star hotel with air condition), solve the language problem, provide transportation from living place to the work place, and insurance out of China, etc.

manufacturer

Welcome to our esteemed Glazed Tile Roofing Sheet Machine, a cutting-edge solution for efficient and precise production of high-quality glazed tile roof sheets. As a leading manufacturer and supplier based in China, we specialize in the design, development, and production of top-of-the-line glazed tile roof sheet roll forming machine material.

Our state-of-the-art machinery is engineered to meet the specific demands of the roofing industry. With our china glazed tile roof sheet roll forming machine, you can effortlessly create stunning and durable roofing sheets that enhance the aesthetic appeal and functionality of any structure. Our machines are designed to handle various materials, including galvanized steel, aluminum, and more, providing versatility in manufacturing options.

As one of the leading glazed tile roof sheet roll forming machine manufacturers china, we prioritize precision and durability in our production processes. Our machines are crafted using high-quality materials, ensuring long-lasting performance and reliable operation. We continuously invest in research and development to incorporate the latest technological advancements, guaranteeing that our machines deliver exceptional results.

At our manufacturing facility in China, we adhere to strict quality control measures to ensure that every glazed tile roof sheet roll forming machine from china manufacturer meets the highest standards. Our team of skilled engineers and technicians work diligently to achieve superior craftsmanship and seamless functionality in each machine we produce.

As your trusted glazed tile roof sheet roll forming machine suppliers from China, we provide comprehensive support and after-sales service. We offer technical assistance, training, and maintenance guidance to ensure optimum performance and longevity of our machines. Our commitment to customer satisfaction has earned us a reputation for excellence in the industry.

Whether you are a roofing sheet manufacturer, contractor, or distributor, our glazed tile roof sheet roll forming machine in china are the ideal choice to meet your production needs. Choose our top-of-the-line machines to enhance your manufacturing capabilities and stay ahead in a competitive market.

Experience the reliability, efficiency, and precision of our glazed tile roof sheet roll forming machines. Contact us, your trusted glazed tile roof sheet roll forming machine supplier china, to discuss your requirements and explore how our cutting-edge machinery can revolutionize your roofing sheet production.