Design Idea:

We have enhanced the thickness of the roller and the diameter of the shaft to produce thicker and larger-sized Purlins. The maximum thickness of purlin is 4mm and the maximum size is 400mm. The heavy-duty c z purlin manufacturing machine has a very stable advantage for the production of large-size Purlins.

Profile Drawing For Reference:

Standard sepcification: Width from 100-400 mm , Thickness from 1.5-4mm , other specail size we can also customized.

| Purlin types | Width a(mn) | Flange b(mm) | Hem c(mm) | Thickness t(mm) |

| C section | 100-400 | 50-100 | 10-25 | 1.5-4 |

| Z section | 140-400 | 50-100 | 10-25 | 1.5-4 |

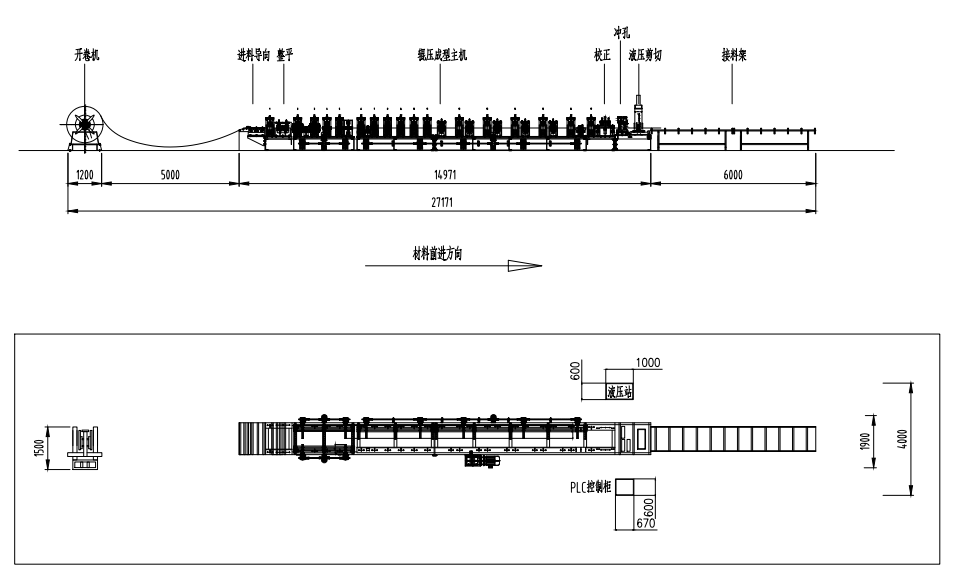

Processing Flow

Uncoiling → Feeding And Leveling →Punching/Pre-Shearing→Roll Forming → Auto Cutting →Products Receiving Table

| C&Z Purlin Rolling Forming Machine | |

| Raw Material | PPGI,PPGL |

| Material thickness: 1-3mm( 15-9 gauge ) | |

| Coil width :150-500 mm adjusted | |

| Machine Frame | Machine base frame is made of U beam weld steel. In the main roll forming machine, there are 2 buttons for urgency stop in case any malfunction happens. |

| Material Of Rollers | High grade 45# forged steel |

| Roller material: Cr12 CNC processing heat treatment to HRC: 58-60 ,finish turning | |

| Forming Stations | Roller stations :23 rows |

| Diameter Of Shafts | Φ90 mm solid |

| Material Of Shafts | 40 Cr CNC processing HRC28-32 ,finish turning and electroplate |

| Forming Speed | Max 30 m/min |

| Voltage | 380v/50hz/3p (As Requested) |

| Transmission Way | By 1.5 inch chain |

| Motor Power | 35KW |

| Cutting Blade Material | Gcr12 quenched treatment |

| Cutting Type | hydraulic post cutting |

| Control | Sizes adjust by PLC control and button C and Z section changing by PLC control |